A successful company must develop its products, technology, and services for the needs of the future. Therefore, we at Advantage Group are constantly striving to improve and perfect these processes involved in the production of quality leather products. We would proudly like to give a tour of our facilities:

Tannery

The Tannery covers an area of about 35,000 sq. meters, and is equipped with the most advanced machinery, such as liming-fleshing machines, hide-shaving machines, and printing machines, etc. all of which are essential to maintain the accuracy and efficiency of the process, which will lead to the high quality of our products.

Leather Store

We have bulk articles in stock according to market needs. Before cutting the leather, our own trained, highly skilled employees select the leather as per garment requirements.

Cutting Section

All the employees in our cutting department are trained in our training school before being assigned to the responsible job of cutting the leather.

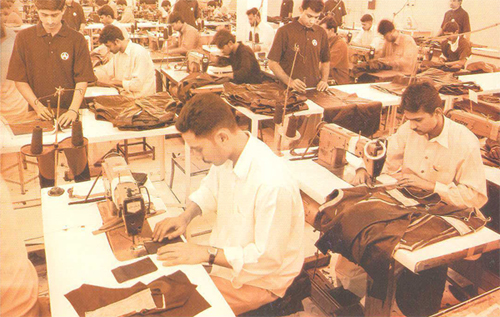

Sewing Section

Our sewing department produces 20,000 pieces per month to meet international requirements.

Quality Control

In respect to our customers’ requirements, we select highly skilled and experienced personnel for quality control. Each piece is thoroughly checked for any flaw, however minor it may be, before being sent off to packing.

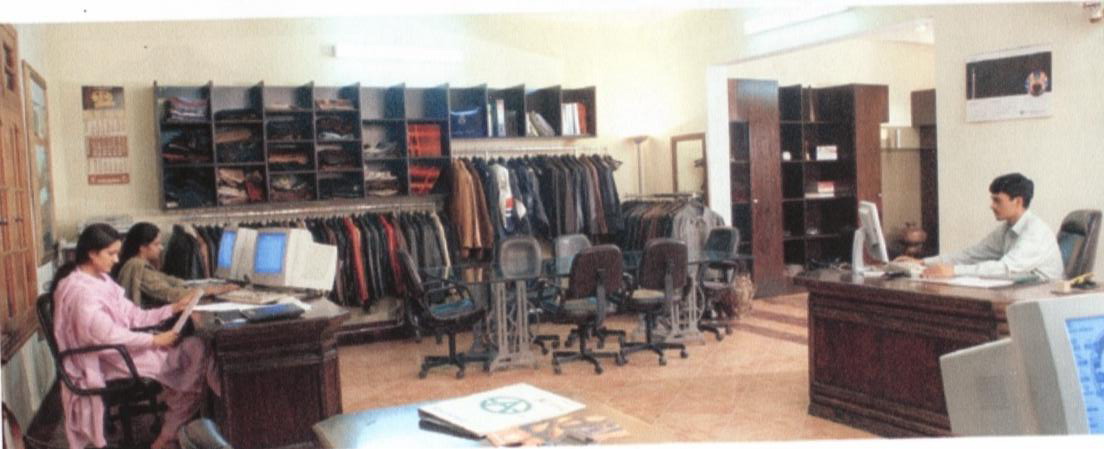

Export Department

Our export department is run by our qualified employees, who are responsible for customer requirements and specifications throughout the process.